Analysis. Optimization. Transformation.

So your processes become more efficient, your decisions more robust, and operational excellence is achieved.

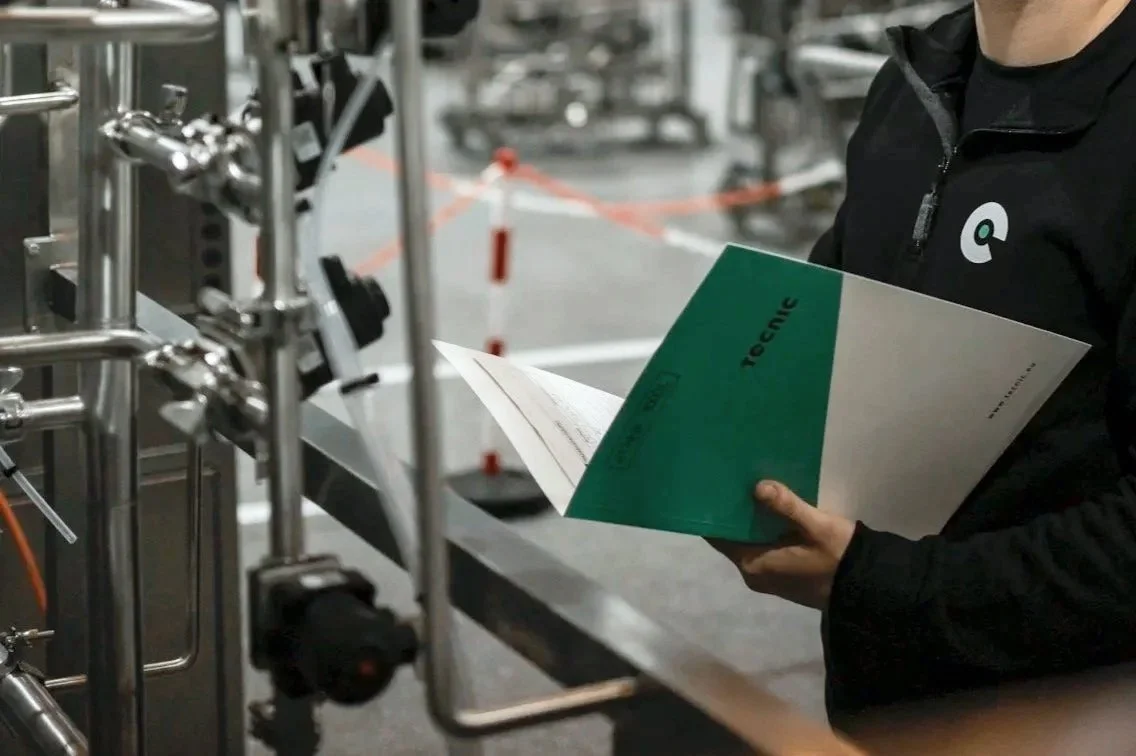

Achieving more together

Through structured approaches that are individually tailored to your company, improvement potential can be identified and translated into viable solutions. This collaborative approach enables us to enhance your operational efficiency and sustainability.

Analysis

Systematically analyze processes and data to identify bottlenecks, dependencies, and root causes. This forms the basis for informed decisions and targeted improvements.

Optimization

Design solutions that optimize processes and eliminate critical vulnerabilities. The focus lies on creating efficient workflows, improving operational stability, and establishing clear, robust structures.

Transformation

Improvements are implemented by translating solutions into day-to-day operations and embedding them into existing processes. Ongoing monitoring and support ensure their long-term sustainability.

Dominik Lardon

Business Engineer for Process Design and Digital Solutions

I combine technical experience with business acumen to analyze and evaluate processes and develop effective solutions. My focus is on making complex systems understandable and designing improvements that work reliably in everyday operations.

Through my studies in Engineering and Management and various projects in production and services, I have learned to take a holistic view of processes – from data and analysis, to process design and optimization, to successful implementation.

Selected case studies

These case studies demonstrate how sound analysis leads to clear insights and how a structured, fact-based approach enables effective, practical improvements. They illustrate how companies can achieve tangible gains in efficiency and quality through clear structures, data-driven decisions, and intelligent automation – even when existing structures are still being developed or data is only available in a simple form.

Analysis of operational processes based on interviews and shadowing

User-centered digitization of manual inspection steps

Reduction of media discontinuities between data capture, documentation, and evaluation

Iterative development and evaluation of prototypes

Economic evaluation based on a cost and revenue model

Development of a rolling planning system

Integrated order and workforce planning

Use of heuristics and optimization methods

Simulation-based scheduling based on the complete order backlog

Ability to adapt to disruptions and short-term changes

Data-driven analysis of demand and inventory trends

Derivation of robust, item-specific inventory planning logic

Reduction in average inventory levels while simultaneously improving service levels

Scalable replenishment concept across a store network

Economic evaluation based on a cost and revenue model